Stainless Steel 316 Flange Head Long Ball Nose Spring Ball Plunger for car

Free sample

- Satisfaction guarantee

- money-back guarantee

- Safe payment

- lower customzied cost

- ISO9001-2007

we would like to ask your something

1 Affordability : Since 3D printing uses only the required material and needs no tooling, it is one of the most affordable manufacturing processes for one-off parts or small batches.

2 geometries: trongse 3D printers create parts layer by layer using a computer-controlled nozzle, they can be used to create highly complex shapes, including complex interior geometries.

3 Efficiency : Once a part has been designed using CAD software, it can be printed in a matter of hours, without a lengthy setup procedure.

4 Adaptability: Because 3D printed parts require no tooling, there is less risk involved when creating a part. If a fault is discovered after printing, it can be amended digitally without the need to replace expensive tooling.

5 Environmental factors : Although 3D printers require power to operate, there is generally no material wastage involved. Subtractive processes like machining, on the other hand, produce waste material.

Description

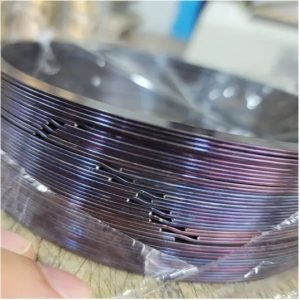

Spring Ball Plunger

|

Product Name

|

All Stainless Steel 304 316 Flange Head Long Ball Nose Spring Load Micro Push Fit Ball Plunger

|

|

Product Type

|

Spring Plunger

|

|

Size

|

M1.5-M5

|

|

Length

|

9.5mm-11.5mm

|

|

Surface

|

Polishing

|

|

OEM

|

Available

|